Wind energy is one of the fastest-growing renewable energy sources, but maintaining high uptime and performance across wind turbines remains a challenge. With harsh environmental conditions, remote locations, and moving mechanical parts, early fault detection and predictive maintenance become critical to reduce costly downtime and extend turbine life.

At IMS Asia, we offer cutting-edge Asset Health Monitoring solutions specifically tailored for wind power plants, enabling real-time performance tracking, predictive analytics, and secure cloud integration.

🌬️ Why Asset Health Monitoring Matters in Wind Energy

Wind turbines operate under constant mechanical stress—gearboxes, generators, and bearings are prone to wear and failure if not monitored accurately. Traditional maintenance schedules often fall short, leading to unplanned outages and higher operational costs.

By implementing real-time condition monitoring, wind farm operators can:

- Detect anomalies early (e.g., bearing wear, gearbox imbalance)

- Schedule maintenance based on actual equipment condition

- Reduce unplanned downtime and extend component life

- Improve overall efficiency and return on investment

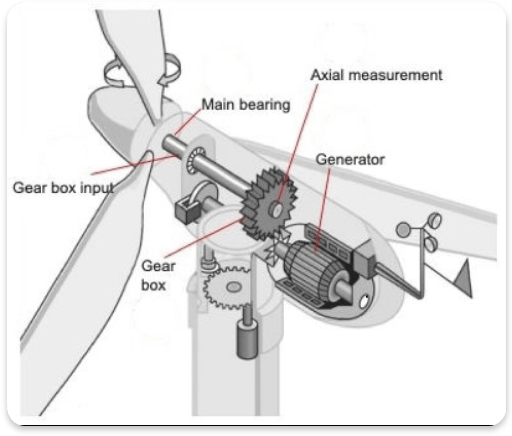

1. Sensor Placement on Critical Components

Strategic sensors are installed at key turbine locations including:

- Main bearing

- Gearbox input

- Generator shaft

- Axial position

Sensors such as vibration, strain, and temperature transducers (e.g., Wilcoxon vibration sensors) provide high-resolution monitoring data.

2. High-Speed Data Acquisition

Sensor data is fed into our rugged DAQ systems, capable of capturing and filtering signals with high fidelity. These devices operate reliably in extreme wind farm conditions and support multiple I/O types.

3. Gateway Integration with Protocol Support

Our intelligent edge gateways aggregate data and provide protocol support for:

- Modbus

- CAN

- EtherCAT

- Profinet

This ensures seamless connectivity with turbine control systems and SCADA platforms.

4. Cloud Connectivity via Ethernet

Using industry-standard communication protocols like MQTT, OPC UA, and DDS, the data is transmitted securely to the cloud. This enables remote access to turbine diagnostics and condition metrics.

5. Web-Based Dashboard & Analytics

Operators and engineers can visualize live and historical data through cloud dashboards on any device:

- Identify performance drops

- Analyze trends

- Set automated alarms

- Plan predictive maintenance

✅ Key Advantages for Wind Farm Operators:

- Reduced maintenance costs

- Condition-based maintenance vs. time-based

- 24/7 real-time monitoring

- Early failure detection

- Remote access and control

⚡ IMS Asia: Powering Smarter Wind Energy

Whether you’re managing a single turbine or a full-scale wind farm, IMS provides scalable solutions for real-time asset health monitoring that help you stay ahead of failures and make data-driven decisions.

📞 Contact us: +65 9339 8013

📧 Email: support@imsaasia.com

🌐 Website: www.imsaasia.com